After what had been a long flight and the invertible wait in baggage reclaim, I headed for the rental car zone. The process of collecting your car for those without status involves completing an insurance waiver, reviewing a checklist, and acknowledging there is no damage to the vehicle as illustrated on the hire car schematic, which is typically signed off before you head to the car park in search of a bay holding the equivalent South Korean model that the rental firm has the match in place of the advertised rental model.

After a quick walk round to see any damage, you usually quickly head off. However, on this occasion, I happened to notice that the person in the rental bay opposite was taking the trouble to video their car inspection using a mobile phone, taking special care to record all the bodywork carefully, the wheels and the interior, also using voice commentary to describe what they saw. What a great and simple idea that provides an accurate account at both ends of the rental process in case of a later dispute.

Completing checklists, taking photographs, and ticking task reminders are standard daily features for most field engineers. Employers have a duty of care, and just because they implement a tick list to remind engineers about vehicle safety, pre-checks for working at heights etc., this does not absolve them from the responsibility of checking their employees are working safely. Indeed, on a recent ‘ride along’ I completed with a field service engineer, he brought out his tablet device and started tapping furiously on his keyboard. When I asked them what they were doing, they replied, “oh, I have to do a vehicle check every morning before being allocated my first work order”.

What was baffling (and very concerning) is that no vehicle check took place as the checklist was completed 100 yards away from the vehicle, but the ‘system’ said the checklist had been completed and compliance was met, right? So, the bottom line is this: Employers have a duty of care, so why don’t more of us use video to truly validate that critical health and safety measures designed to protect the employee are being adhered to?

Why don’t more of us use video for asset or equipment compliance inspection, work debriefing, problem triage of linear assets? Especially as video technology has now improved and combined with machine learning (ML) and artificial intelligence (AI) which can convert the video and audio stream to searchable reference data, meta tagging the images, timeline, and location details.

Video naturally changes behaviour and makes carrying out those vital checks something that happens organically as a way of working…

Video recording has never been easier; even my father of ninety-two years loves using the video features of his mobile phone. However, many service organisations (80% in our survey) are worried about the high data costs associated with the mobile to cloud transmission and storage of video files securely.

But video naturally changes behaviour and makes carrying out those vital checks something that happens organically as a way of working. There is no way to avoid undertaking the task- in other words, it becomes natural as part of the standard operating flow.

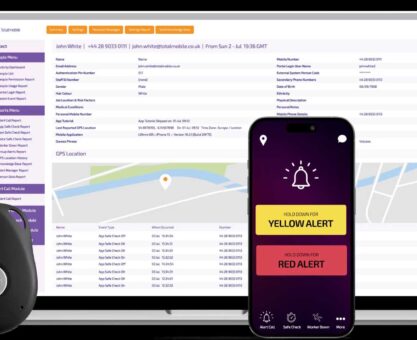

Good news: a new software vendor has produced an App that is now available directly to customers of the most popular Field Service Management Software solutions to integrate video recording, uploading, and playback straight to the field service engineers’ handheld. This technology adopts the latest video compression technology for a vastly reduced, in some cases, almost zero data storage cost as they don’t store the content on the Field Service platform, thus vastly reducing video file size, and with storage and streaming included in the subscription, resulting in zero on-platform storage costs.

A unique ability to overlay guiding instructions to the engineer within the video recording that is available offline is thus different from other solutions like assisted reality AR/VRA commonly used by call centres or live video calls equally valuable for agent to customer diagnostic work. Offline or asynchronous guided video feed makes the recording and commentary capture simple and valuable for engineers and technicians.

The resulting recording is processed using voice to text machine learning to create meta tags. The video recording has a mapping geotag of the location, and video images are further processed for bar codes, QR codes, products and assets recognition or other images of note.

The rules and regulations must be clearly defined, procedure and process that has checks and balances prescribed, and training and ongoing support provided

An example of this that is related to compliance is the engineer safety site survey on arrival and upon leaving, documenting the site, and archiving the “as found” working environment. This is a classic use case when several contractors are working on-site, and the project needs to follow a schedule of events.

I mentioned earlier that Employers have a duty of care, but for many service leaders, employment, and health safety regulations, they have additional quality management and regulatory compliance. This compliance risk and its mitigation is a significant worry that both carry a legal, financial, and reputational risk for failing to act under internal governance, external regulations, or legislature.

The rules and regulations must be clearly defined, procedure and process that has checks and balances prescribed, and training and ongoing support provided. Plus, a means to audit and analyse failings through root cause analysis recorded. Any decline or deviation of standards is considered and documented. Penalties for non-compliance especially involving the most severe accident or incident, can be heavy.

As Service Leaders, we should be more than ever mindful of evaluating and auditing our approach to preventing corruption, ensuring good employee behaviour, complying, and demonstrating adherence to workplace health and safety, environmental impact, data management, quality, and social responsibility.

To help us, we need to seek initiatives that help leverage technology to find simple ways that do not unreasonably burden our field service engineers with endless checklists and clickable checkboxes; maybe video and the new use of ML/AI gives us a new and powerful tool.